Total Quality Management: Its Concept, Principles, and Importance in Business

In the advanced and constantly changing world of business, Total Quality Management (TQM) has become a fundamental concept for success. This philosophy, focusing on continuous improvement in all aspects of operations, strives to achieve the highest level of customer satisfaction. In this article, we delve into the concept of Total Quality Management, its principles, stages of implementation, tools used in its execution, and how Wafeq can aid in achieving quality in companies.

Concept of Total Quality Management

Total Quality Management is a strategic concept aimed at achieving continuous improvement across all elements and functions of an organization. This concept focuses on achieving customer satisfaction by improving quality across all aspects of operations, from design and development to production, services, and support. Employees are a crucial part of this process, being encouraged to participate in improving quality and developing processes.

Objectives of Quality Management

There are several key objectives of quality management that companies should aim to achieve. First and foremost, it is about achieving customer satisfaction by delivering products and services that exceed expectations. Secondly, quality management aims to improve the processes and procedures within the company to minimize errors and increase efficiency. Lastly, quality management strives for sustainability and continuous improvement, with a focus on fostering a general culture of quality throughout the organization.

Experience the power of exceptional quality management with Wafiq's accounting software! Empower your business with comprehensive financial reports that drive precise decision-making. Unlock access to a suite of indispensable features and tools designed for optimal business management.

Experience the power of exceptional quality management with Wafiq's accounting software! Empower your business with comprehensive financial reports that drive precise decision-making. Unlock access to a suite of indispensable features and tools designed for optimal business management.

Principles of Quality Management

- Quality Management is based on a set of fundamental principles that guide companies toward continuous improvement and success. These principles include:

- Customer focus: The first and most important goal of quality management is to achieve customer satisfaction and meet their expectations.

- Leadership: Effective leadership is key to achieving quality. Leaders must set direction and goals and encourage teamwork.

- Engagement of people: Everyone in the company should be involved in achieving quality, from top management to frontline workers.

- Process approach: Quality management should be conducted as an integrated process that encompasses all aspects of work.

- Continuous improvement: The goal is to achieve continuous improvement, not to be satisfied with the status quo.

- Evidence-based decisions: Decisions should be made based on accurate analysis of data and information.

- Relationship management: Building good relationships with partners and suppliers to achieve continuous improvement.

Stages of Implementing Total Quality Management

- Implementing Total Quality Management requires a strategic and thoughtful perspective. Here are the basic steps:

- Management Commitment: This step requires the commitment of top management to continuous improvement and quality.

- Formation of Quality Teams: This involves forming cross-functional teams with representatives from all levels within the company.

- Provision of Training: Providing necessary training and development for employees to understand quality principles and tools.

- Application of Statistical Tools: Using statistical tools to measure performance and identify problems.

- Process Improvement: Continually working to improve processes and performance based on the data and information collected.

- Review and Continuous Improvement: Regularly assessing performance and working on continuous improvement.

Tools for Implementing Total Quality Management

Some many tools and techniques can be used to implement Total Quality Management, including:

Charts: Graphs such as control charts and histograms can help analyze performance and identify patterns.

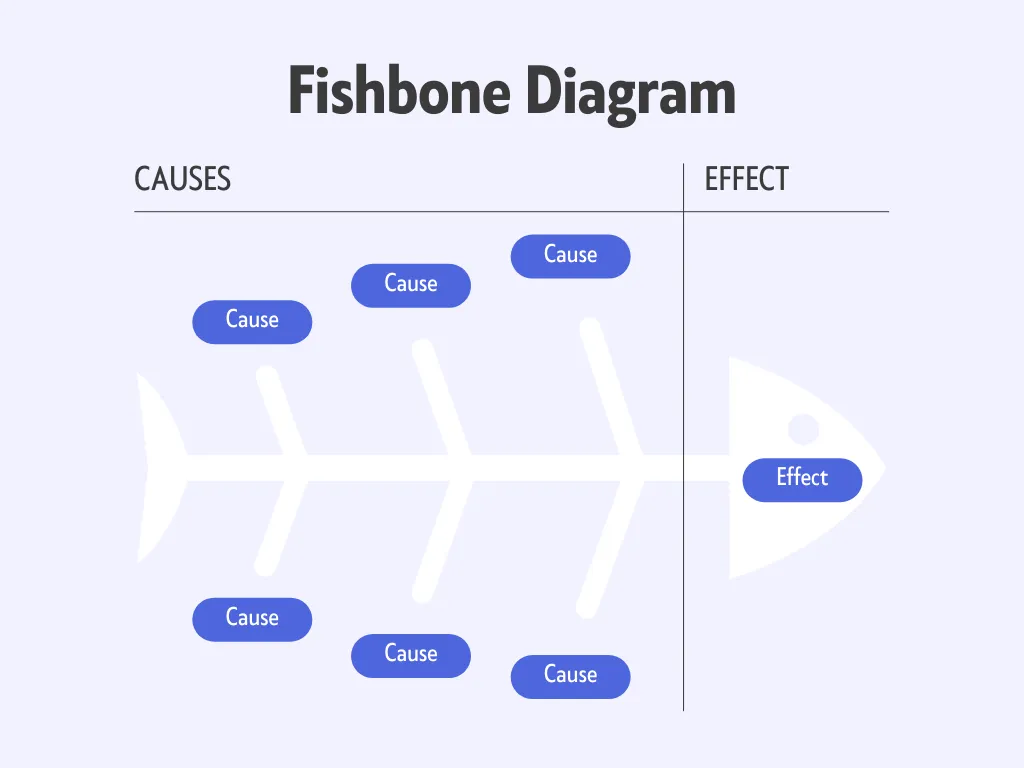

Fishbone Diagram: Helps in identifying root causes of problems.

Pareto Analysis: Helps identify the most important issues to focus on.

Process Analysis: Helps understand processes and identify potential areas for improvement.

Relation Diagram: Shows relationships between causes and effects.

Obstacles to Implementing Total Quality Management

Despite the significant benefits of implementing Total Quality Management, companies can face a number of challenges, including:

Lack of management commitment: Full commitment from top management is essential for the success of any quality strategy.

Lack of training: Adequate training should be provided to employees to understand and apply quality principles.

Resistance to change: Change is always difficult, and some individuals may oppose efforts to improve quality.

Lack of resources: A lack of necessary resources such as time, money, and labor can be a significant obstacle.

Focus on short-term goals: Achieving total quality requires a focus on long-term goals.

How does Wafeq help in quality management in companies?

Wafeq is an integrated accounting software that can help companies improve the quality of their accounting processes. Wafeq offers features that support quality management, including:

Financial performance tracking: Wafeq can provide accurate financial analytics that helps identify areas needing improvement.

Internal auditing: Wafeq allows for the internal auditing of financial data, helping to detect possible errors and issues.

Compliance with accounting legislation: Wafeq can help companies stay compliant with applicable accounting rules and regulations.

Providing software training: Wafeq can provide necessary training to employees to ensure their proficient and effective use of the software.

Read more: Lean x Wafeq: A Fintech Success Story (5 entities in 5 months).

The Role of Employee Training in Quality Management

Employee training plays a crucial role in quality management in companies. Training helps employees understand quality requirements and how to achieve them in their daily performance. Some key points about the role of training in quality management include:

- Enhancing understanding: Training helps employees understand quality standards and the company's expectations.

- Skill development: Training can aid in developing the skills needed to achieve quality in all company activities.

- Facilitating continuous improvement: Training can achieve continuous performance improvement by teaching employees the latest practices and techniques.

The Impact of Quality Management on Customer Satisfaction

When companies invest in quality, customers notice the difference, which can increase their satisfaction and loyalty. Some key points about the impact of quality management on customer satisfaction include:

Quality means delivering products and services that meet or exceed customer expectations, leading to greater satisfaction. Quality enhances trust between the company and its customers, contributing to building strong, lasting relationships. Quality management leads to better service and more respectful treatment of customers, elevating their level of satisfaction.

The Role of Technology in Quality Management

Technology plays a crucial role in enhancing quality management. Thanks to technological advancement, companies can monitor and improve the quality of products and services in new and effective ways. Some key points about the role of technology in quality management include:

- Automation: Technology can enable automation for processes that were previously costly and prone to errors.

- Accurate analysis: Technological tools can provide precise analytics that help companies understand performance and identify areas needing improvement.

- Effective communication: Technology facilitates communication among work teams, allowing quality to be implemented more effectively.

Case Studies of Successful Quality Management

One company that has greatly benefited from total quality management is Toyota Motor Corporation. By implementing the "Toyota Production System," which focuses on eliminating waste and improving efficiency, Toyota has been able to achieve high levels of quality and performance.

This strategy has led to significant improvement in customer satisfaction and the company's success. Data has shown that customer satisfaction rates have increased by 15% over the past five years, and the company's revenues have increased by 20% in the same period. Additionally, Toyota has been able to reduce production errors by 25%, leading to improved quality and reduced costs.

The Relationship between Quality Management and Continuous Improvement

Continuous improvement is a fundamental element of quality management. Its aim is to constantly enhance performance and improve processes. Within quality management, continuous improvement is encouraged as part of the organizational culture. Companies that adopt this approach consistently monitor the performance of their products and services, always looking for ways to improve them.

Continuous improvement helps companies stay ahead in an ever-changing market, and it assists in achieving optimal quality and performance. Some examples of continuous improvement include improving processes, developing products, and enhancing efficiency.

Measuring the Effectiveness of Your Quality Management Systems

Measuring the effectiveness of a quality management system requires identifying key performance indicators that reflect the company's business goals and priorities. These indicators might include customer satisfaction rates, the proportion of errors or defects in production, and operational efficiency.

In addition, companies should regularly analyze data to assess system performance and identify areas needing improvement. This might include direct measurement of performance against set standards, and a review of historical data to identify trends and patterns.

Quality Management and Compliance with Industry Standards

Quality management plays a crucial role in ensuring compliance with industry standards and government regulations. Providing high-quality products and services requires adherence to a range of industry-recognized standards, such as the ISO 9001 standards for quality management systems.

Compliance with these standards not only ensures quality but also builds trust with customers and business partners. Additionally, compliance can help reduce risks and achieve continuous improvement in performance and efficiency.

Conclusion

By adopting an effective quality management system, companies can achieve high quality in their products and services, along with continuous improvement. Quality management is not just about superior quality, but also about achieving company objectives and improving performance. With the right tools and techniques, any company, regardless of its size or the industry it operates in, can successfully implement total quality management.

Use Wafeq - an accounting system to keep track of debits and credits, manage your inventory, payroll, and more.

Use Wafeq - an accounting system to keep track of debits and credits, manage your inventory, payroll, and more.

.png?alt=media)